Sugar Melter

Sugar melting is a common process in Refineries, Cane & Beet Sugar Factories where the melt has to be produced at constant specified brix and temperature.

Sugar Melter Overview

Controlled brix, temperature & optimum retention time using minimum Power, Steam & Water ensures the consistency of the melt quality.

Looking in to the operational difficulties like use of exhaust / live steam, water and poor control of temperature & brix in conventional melters, SED introduces an energy efficient design for sugar melting system.

Distinctive Features:

Highly Competitive Operation:

- Operation under vacuum / low pressure.

- Accurate brix and temperature controlling.

- No use of live steam / exhaust steam.

- Melting by syrup / water.

- Variable retention time possible.

Exclusive Design:

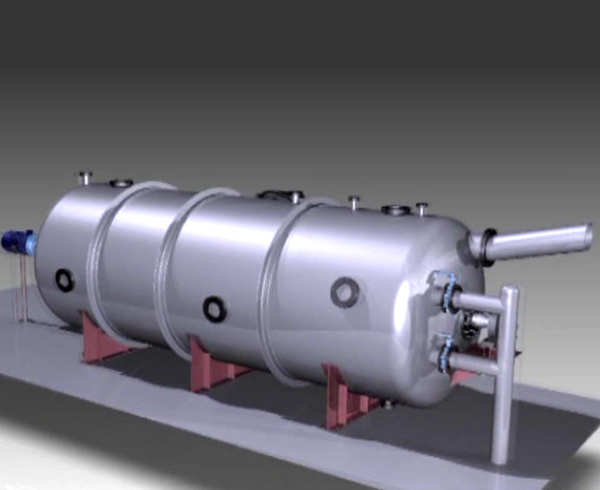

- Stainless steel horizontal cylindrical vessel having capability to handle melt up to 70-71Brix.

- Horizontal stirrer with paddles ensures no short-circuiting & undissolved crystals, hence giving an efficient plug flow system.

Low steam consumption:

- Utilization of low temperature vapours of 70-80°C in vacuum.

Minimal power consumption:

- Possibility to avoid magma pump by vacuum sucking, if located nearby.

- Efficient in- line planetary drive consuming less power.

Automated control:

- The flow of melt, syrup and hot water can be put on automation to achieve controlled output brix & temperature (optional).

- Brix Sensors, with Microwave Sensing Technology ensure constant brix of melt.

- Auto-alarming indication for level fluctuation.