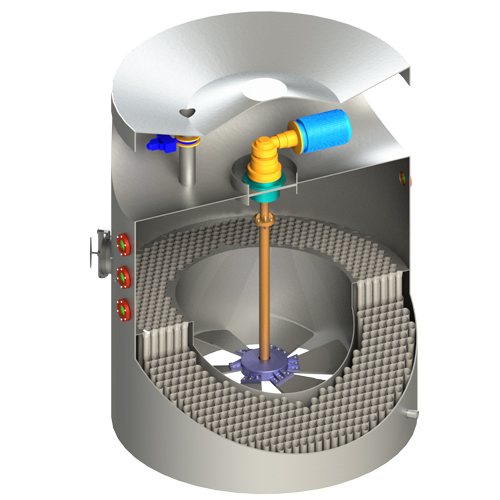

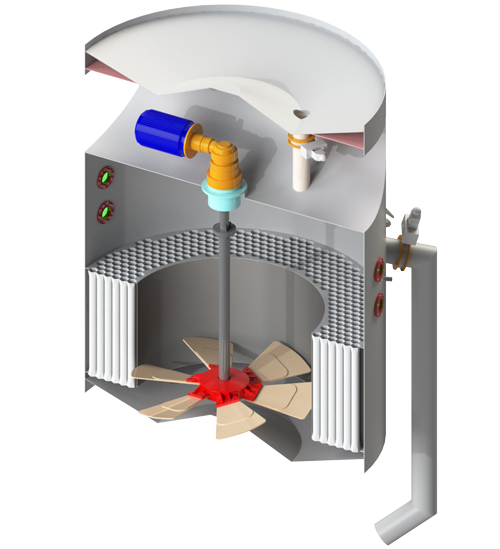

Mechanical Circulator

Mechanical circulators are installed in vacuum pans of sugar industry in order to reduce the boiling time. It is also used in reduction in sugar colour and an increase in pan yield. In batch pan, mechanical circulator improves exhaustion, capacity and maintains uniform pan boiling & crystal formations. Spray Engineering Devices Limited (SED)'s innovative Mechanical Circulator technology has achieved remarkable growth of crystals and exhaustion of molasses in its application to sugar industry.

Mechanical Circulation is associated with various advantages at the level of industry viz.

Quality Improvement

Improved crystal size distribution and low sugar colour due to uniformity of fluid conditions within the vacuum pan. This is a consequence of the better circulation leading to more homogeneous crystallization conditions within the pan. The crystals grow more evenly and there are non-sugar liquor inclusions. There is less-colour in sugar and reduced risk of sugar losses by local overheating.

Homogeneous Massecuite

Homogeneous massecuite with reduced fine grain formation, conglomerates and color formation.

Recovery

A high massecuite dry substance concentration is possible, leading to a higher crystal yield and a lower purity of molasses.

Reduction in Water Consumption

In addition stirring also reduces centrifugal wash water consumption by 50% due to uniformity of crystals.

Height of Massecuite

The height of massecuite above the calandria may be pushed considerably above what is reasonable with natural circulation. Hence a gain in capacity and a decrease in graining volume.

Capacity Enhancement

The mechanical circulation improves heat transfer rate and so shortens the duration of the batch boiling, thus improving capacity.

Energy Efficiency

Low ∆T between heating steam and massecuite are only possible with the use of stirrers. A reliable operation without stirrers (mechanical circulation) is not possible and may lead to sedimentation of the crystals. The use of lower pressure vapours becomes possible (e.g. shifting from 2nd to 3rd to 4th evaporator effect), resulting reduction of the factory steam requirements.

Less Fouling/Scaling/Deposition on Calandria Tubes

There is less fouling/ scaling/deposit on the tubes, due to the abrasion effect by friction of the circulating crystals.

Distinct Features

- Enhanced circulation capacity due to more number (six) of blades.

- Reduced/Minimized boiling time.

- Variable speed circulation with VFD compatible with crystallization rate trend.

- Uniform circulation and better heat transfer rate.

- Uniform and improved crystal size with sparking luster.

- Reduced centrifugation time and wash water quantity.

- Unique compact design mechanical circulator.

- Lower hub size with higher sweeping volume.

- Easy installation due to direct mounting without any structure or platform.

- Highest efficiency with inline planetary drives.

- High quality mechanical seals.

- Casted bearing housing design.

- Having high efficiency to protect any air/fluid leakage.

- Suitable for high temperature and pressure conditions with extended life and low maintenance.

- Detachable impeller blades for additional flexibility.

- Low power consumption.

- Fully automated control and monitoring system.

- Low maintenance requirement.

- Available in various models as per capacity.

- Patented technology.

Benefits

- Saving in strike time of up to 30%.

- Good circulation maintained through the strike.

- Produce more uniform grain.

- Increased pan capacity by 25-30%.

- Increase in crystal yield up to 5%.

- The color removal has improved from 87% without circulator to 95% with circulator.

- Sugar conglomerates counts have been reduced by about 85%.

- Strike level in pans can be raised by 30-40 cm with the use of stirrer.

- Increase in heat transfer coefficients from 0.78 kW/m2/oC to 0.87 kW/m2/oC with stirrer.

Available Models:

| S. No. | PAN CAPACITY | INSTALLED POWER* |

|---|---|---|

| 1 | 25T – 30T | 22 kW |

| 2 | 30T – 40T | 30 kW |

| 3 | 40T – 60T | 45 kW |

| 4 | 60T – 80T | 55 kW |

| 5 | 80T – 100T | 75 kW |

| 6 | 100T – 120T | 90 kW |

| 7 | 120T – 150T | 110 kW |

* Operating at 33/48/63 rpm with VFD depending upon pan duty, design & operation on various viscosities.